I was recently on a service job and watched the tech surge test the compressor. I’ve seen it done a number of times but for some reason a question came into my mind.

I know the tech is manually manipulating the inlet & bypass valves to increase the unit pressure thus forcing the compressor into a surge condition. He is listening for the whooshing sound a compressor makes when the max pressure is reached and the air slips into a reverse flow.

The question that hit was how exactly does the controller know when a surge condition has been experienced. A quick call to my service manager got me the explanation I wanted and I thought you too might benefit from knowing the answer.

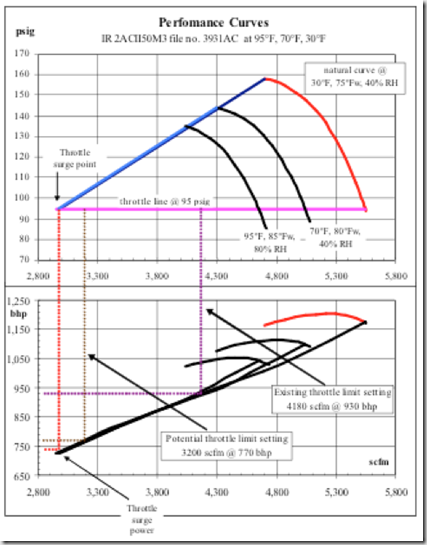

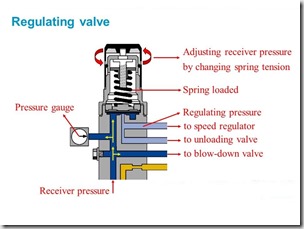

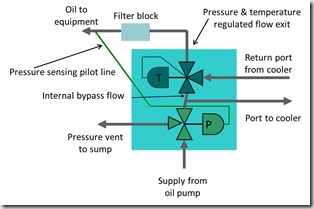

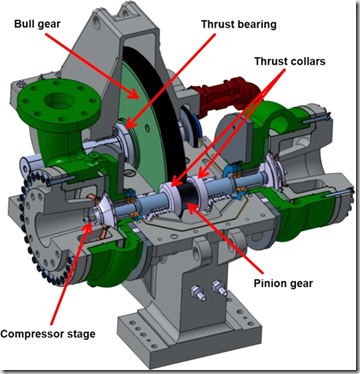

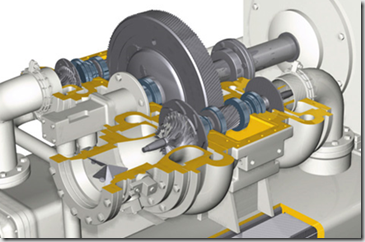

The controller is always looking at the unit pressure. Not just the final discharge pressure but also the pressure at each stage of compression. The controller registers a surge when it see a simultaneous drop in pressure and a drop in motor amps. The controller can register the surge regardless of which stage the pressure drop occurred. Meaning the surge could have occurred in any stage of the compressor, not just the final stage.

Once the controller reaches the pre-set surge count, which is usually programmed by the technician setting up the unit, it pushes the surge line out so the compressor should not reach this point again. By limiting how far the compressor can go the controller keeps surge from occurring again.

Now that the controller has automatically compensated for the compressor surging we need to further consider: Why did the compressor have a high number of surges?

This could be caused by a number of reasons including compressor component wear. Perhaps the impeller or diffuser has been worn by particulate or water erosion which now limits the ability of the compressor due to a change in tolerances. More likely, the cause can be attributed to a change in ambient conditions. Very likely a temperature change in the air inlet temperature or a change in humidity has occurred or a combination of both.

Further consider that while the controller has modified settings to protect the unit from further surges it has also taken away a potentially useful area of operation. You see the controller can push the surge line out to prevent further operation within the effected surge area but it will not reverse the line in the opposite direction. So when ambient conditions again allow compressor operation within the previous zone the controller will not allow operation back within this area without being forced.

To force the controller to allow operation within this zone again a manual tuning must be done to override the controllers automatic pushing of the surge control line. Think of this as a reset of the controller’s parameters so to speak.

To accomplish this the unit is manually tuned to the proper control set points by a certified technician or knowledgeable operator.

For this reason we recommend manual control tuning be performed at the beginning of each seasonal weather changes. So as the temperatures begin to rise in the late spring or the temperatures begin to drop in late fall the compressor should be manually tuned by your authorized service company.

When we are selected to provide a preventative maintenance or closed cost service contract we actually retune the compressor each quarter. If your company is without a contract we recommend at least retuning the compressor twice per year.

As always, if you have any questions, feel free to contact me to discuss further.