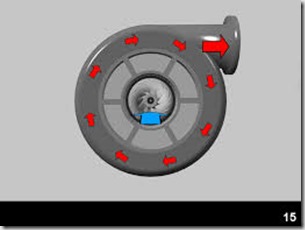

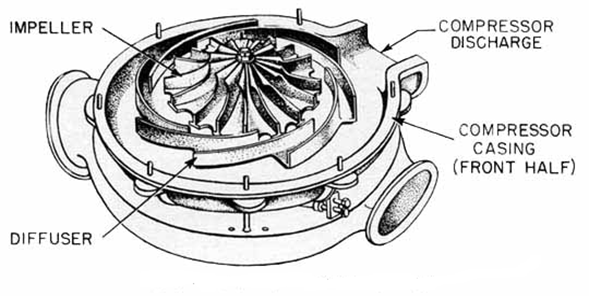

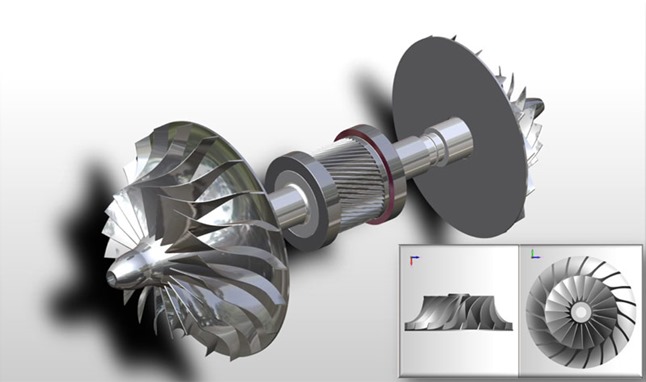

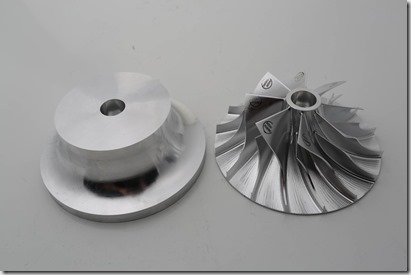

We’ve previously discussed that high velocity air leaving the impeller impacts the blades on the diffuser which slows the air which causes the air pressure to rise. The next component in a centrifugal compressor is the scroll. Sometimes referred to as the volute.

Once the air passes through the diffuser blades it enters the scroll. As you can see in the above picture, the air passes around the scroll and exits at the top right discharge port. The air passing through the scroll is further reduced in velocity in which again causes a rise in pressure.

At this point the first stage of compression is finalized resulting in the final pressure from the 1st stage of compression which typically results in a discharge pressure of approximately 14 PSIG on a 100 pound compressor design. Remember, the aerodynamic engineer can alter the various aspects of the impeller, diffuser and scroll to achieve various outcomes.

It’s also important to note that we likely started with an inlet pressure to the compressor at approximately 14.3 PSIA. The absolute atmospheric pressure at the location of the compressor. This location and subsequent absolute pressure are critical considerations for the compressor. A machine designed for installation at the beach (sea level) with an absolute pressure of 14.7 will not have the same performance if it is moved to a mountain in Denver with an atmospheric pressure of 12 PSIA.

Always assure you’re using the correct readings, whether PSIG or PSIA. Gauge pressure vs. absolute pressure makes a huge difference. It’s also interesting to note that most of the work related to pressure increase on a centrifugal compressor is done in subsequent stages.

The secondary function of the scroll is to provide a smooth collection of the air where it will be passed to the next section of the compressor. The next section could be discharge to the plant, discharge to the next stage of compression or most commonly to a cooler.