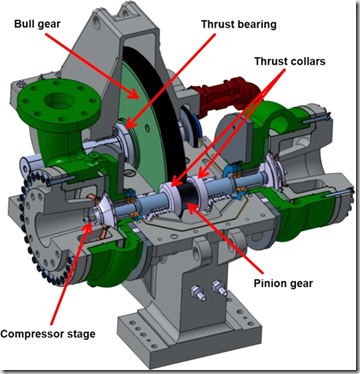

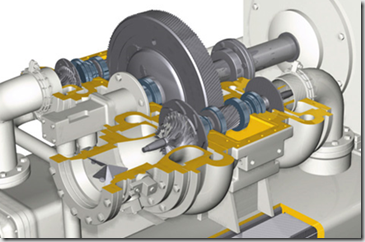

Our focus has been on the integral geared centrifugal compressor. This arrangement calls for several pinions shafts (previously discussed) to mounted around a central drive gear, commonly called the Bull Gear.

The exploded view of a bull gear (left) shows the helical gearing that will mate with the pinion gear located on the pinion shaft.

The advantage of the integral geared centrifugal is where the bull gear drives multiple pinion shafts, each shaft can be speed altered with simple gear changes.

This arrangement is unlike a barrel type centrifugal compressor where all the stages are driven at the same speed. This allows each pinion to run at different speeds thus allowing every impeller pair (or single) to operate at it’s optimum aerodynamic speed. This results in higher efficiencies along with the ability to package the unit in a smaller space.

The bull gear is typically driven by an electric motor at 3600 RPM although various manufacturers may use motors with a rotational speed of 1800 RPM depending on the compressor application. It should also be noted that in many cases the bull gear can be driven by a steam turbine. This is a particularly advantageous situation when a large facility has excess steam or the unit can be used as a steam pressure reduction valve (PRV). In this instance the operational cost of the compressor can be lowered or completely eliminated.