How do we keep the air flowing where we need it to go? Control valves!

In a centrifugal compressor the unit is controlled by several valves.

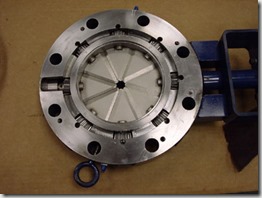

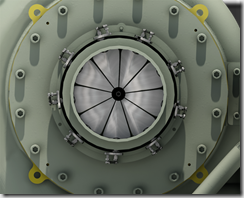

Inlet Valve

The inlet valve or Inlet Guide Vanes (IGV) controls the amount of air allowed into the 1st stage of compression. The valve can be as simple as a butterfly valve or more commonly an inlet guide vane which functions as the inlet valve. The advantage to utilizing the IGV is the incoming air can be pre-swirled to assist in getting the air moving in the correct orientation for the 1st stage impeller to pick up and compress the air.

Discharge Valve

The discharge air adjust how much air is allowed to leave the compressor and enter the plant piping system. Personally I prefer the term blow off valve which is simply a valve the blows the compressed air to atmosphere if it is not needed in the plant compressed air piping header. The most efficient compressors will utilize modulating blow off valves rather than an open/closed arrangement which allows for much finer control of the air that blows off to atmosphere. It is important to note that the most inefficient aspect of centrifugal compressors is blowing off air that you have just paid money to compressor!

Discharge Check Valve

The discharge check valve is used on the discharge of the compressor to prevent any opportunity for compressed air from the plant header system to backflow into the compressor while it is running unloaded or off. The backwards flow of air into a centrifugal compressor can spin the impellers in the opposite direction causing massive damage to the unit.

Isolation or Block Valve

A secondary valve on the discharge air line to again prevent any backwards flow of air into the compressor.

All of these valves are controlled by the compressor control system.