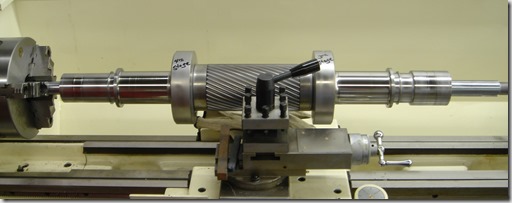

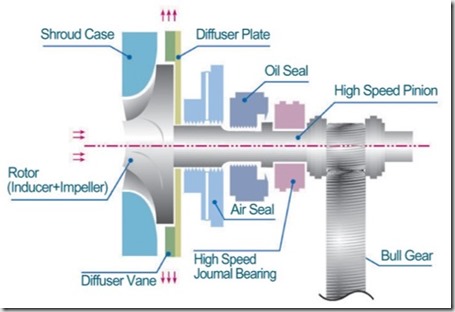

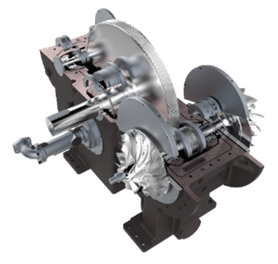

We previously discussed the pinion. The shaft where the impeller, bearings and seals are mounted prior to the assembly being placed in the gearbox. As with any rotating equipment, there are mechanical forces seeking to wreak havoc within your centrifugal compressor as well as air and oil flowing throughout the machine. Today we discuss how everything is held in place with bearings and seals.

Bearings: Radial

There are a couple bearing designs that carry the pinion with the best & most prevalent option being a split, tilt pad bearing. The multiple pads are free to move about a pivot. The number of pads & preload can be varied to achieve the desired performance. The split design allows the bearing to be dis-assembled in the field for inspection and repair.

An alternate to the tilt pad bearing is termed a “Hydrostatic squeeze film Babbitt sleeve bearing”. This bearing is used by a single manufacturer and while the bearing does hold up well in the application it does not maintain the ability to field inspect / repair. For this reason, this particular manufacturer supplies what is termed a “rotor cartridge”. This terminology basically means that the pinion is supplied with the bearings, seals and impellers installed and balanced for either placement into a new compressor or to be sent to a client for a repair installation in the field. While this sounds like a time saving feature for the end user it actually just locks down the client requiring all repairs to be returned to the factory. While the virtues of this design might be praised by the manufacturer it can be noted that this is NOT the arrangement the manufacturer uses in their custom designed compressors! If a tilt pad bearing is used on high performance compressors, wouldn’t you prefer this same design to be used on your smaller plant air compressor too?

Bearings: Thrust

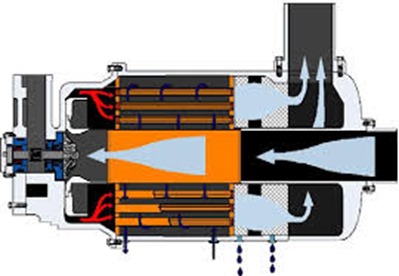

Thrust within a centrifugal compressor is a given. The question is: How is the thrust limited?

For thrust, think of a box fan. When the fan is running at low speed the box is stable. However, if the fan speed increases the pressure increases with the air movement from the blades pushing against the static air or perhaps a window screen. In this circumstance the fan is likely to fall over backwards from the force.

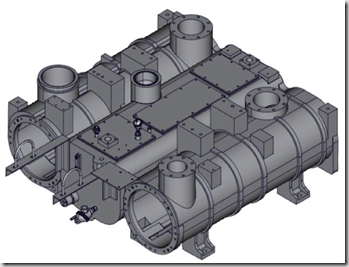

This same axial force is present in a centrifugal compressor. The impeller moving the air forward pushes the pinion shaft in the opposite direction. Additionally, the helical gearing used for integrally geared compressors create their own axial thrust issues and the force also changes as the load requirements change thus creating a change in the amount of air being pushed through the stage. As the clearances are extremely tight within the compressor, pinion movement could cause an impact within the compressor and thrust bearings are therefore used to limit this movement.

Some manufacturers install bearings on the pinion itself to limit this movement while others use thrust collars to transfer the movement force to the larger bullgear where the thrust load can be taken by much larger thrust bearings. In my opinion, the larger the surface taking any load, thrust or otherwise, is a better, more reliable option.

Seals

As previously discussed there will be 2 seals on the pinion at each impeller placement. One being the air seal to eliminate any compressed air leakage and the other to eliminate any oil migration into the air stream.

There are 2 basic types of seals used for these applications. One being a carbon ring seal and the other a labyrinth seal.

The carbon ring type seal physically contacts the shaft to seal either the air in or the oil out. A drawback to this type seal is the wearing component that contacts the shaft. As the rings inner bore wears the clearance of the seal opens allowing leakage. This requires shut down of the compressor for maintenance (replacement) of the seal.

The alternate seal type is a labyrinth seal which provides a tortuous path to prevent air or oil migration. The biggest advantage of a labyrinth seal is that this type of seal is non-contacting and will not need maintenance (replacement) under normal operating conditions.

While every component within a centrifugal compressor is crucial, bearings and seals are extremely critical items and care should be taken to make sure you understand how your compressor or a newly proposed compressor operates. Obviously, the manufacturer’s choice of bearing and seal arrangements are determined by the cost of the arrangement as well as the desired life of the component. Always have an in depth conversation with your compressed air professional to assure your understanding of your air compressor.