Todays topic is automatic drain valves. We’ve discussed hot weather, cooling water temperatures and air dryers over the past several weeks. Regardless of how cold your cooling water is or how clean you’ve kept your air compressors and coolers, all of your efforts are in vain if you don’t get the condensed water out of the system. Enter the automatic drain valve!

Drain valves come in a variety of configurations but they all attempt to perform the same task. Once you have condensed the water vapor that has infiltrated your compressed air into a liquid form, the water then has to be removed from the system. Coolers have a separator that removes the water from the air, filters remove the water from the air which then ends up in a collection area of the filter housing and depending on the location, water can also collect in air receivers. The collection area of each device will normally have a valve that can be opened to drain the collected water and direct it to a sewer or holding area.

However, most companies will not pay a maintenance tech to stand at each collection point to open the valve to drain the water so automatic drains are installed at these areas. It is crucial to keep these drains in top operating condition as when the auto drain fails the collection area of the separator, filter or air receiver fills with water. At this point additional water that is condensed has no place to go except downstream which is the exact problem we’re trying to eliminate.

Prior to discussing the various types of drains, it is vital to note that when using lubricated compressors the condensate that is discharged will also contain trace amounts (hopefully just trace amounts) of compressor lubricating oil. Nearly all municipalities frown highly on this oil reaching their water treatment systems and large fines may be imposed if this occurs. While we are experts in oil free air, many readers of my blog do incorporate oil lubricated compressors which is the reason for my cautionary statement. For lubricated compressed air systems the use of oil/water separators is highly recommended to remove any lubricant from the water prior to discharge.

Timed Solenoid Automatic Drain Valves

The timed solenoid auto drain has been around for many years and has been used in a variety of applications. The operation is simple in that the solenoid triggers at timed intervals which allows the valve to open. You will note on the photo that there is a dial to allow the timing of the valve to be adjusted. So for high water loads the valve can be set to actuate every minute or if the water loads are low you can extend the operation to only occur once every 45 minutes. The actual range on the unit shown is 1 minute to 60 minutes. Looking a the photo above you will also note a second dial which modifies the duration of the cycle. This allows a specific time that the valve will remain open each time it actuates. For example the valve can be set to actuate every 5 minutes and remain open for 10 seconds or any combination the user selects. The actual duration of the valve pictured can be set between 1 to 60 seconds.

This valve is often incorporated into systems because of the inexpensive cost to purchase but as with most inexpensive solutions there are hidden cost to consider. When this valve actuates, not only is water discharged but also compressed air that we have just spent money for the compressor to compress. Now we simply vent this expensive compressed air to the atmosphere where the benefit is lost. These valves typically operate on 110 volts and while the electric use is slight there is still an expense. One of the most important items to note is the valve, since solenoid actuated, has a very small opening. While the main valve seen above looks to have rather large openings of 1/4″ to 1/2″ the actual opening in the valve is quite small. On this particular unit the manufacturer specifies a healthy 5/32” orifice size. The small opening lends itself to contamination plugging the valve. The valve must then be cleaned and worse, is not operating to remove the water from the system until someone notices there is a problem.

Full Port Ball Valve Drain

The full port ball valve drain was introduced to eliminate the clogging problems associated with the solenoid type drain valves. This valve type is available from 1/2″ to 1 1/4″ with a full port ball valve that is rotated to open and continue the cycle to close the valve. These units typically incorporate a powerful motor capable of driving the ball past any debris that might collect and are therefore very reliable. The operation of this unit is based on a time schedule set by the user. This type of drain is consuming electricity to operate and also discharges valuable compressed air while purging the condensate. As expected, the ball valve type drain has a higher initial investment than the previously discussed solenoid type drain but vastly increases reliability.

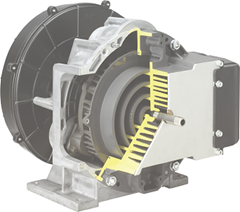

Zero Loss Automatic Drain Valve

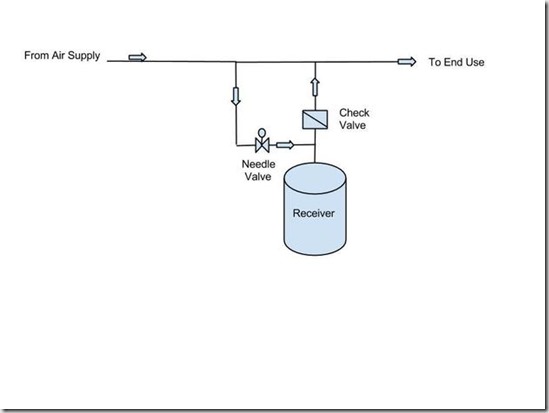

The premier drain valve is one that actuates when it senses there is enough water in the system that needs to be evacuated, uses no electricity, is reliable and does not expel valuable compressed air with the condensate. Enter the zero loss type automatic drain. These drains are pneumatically operated and require no electricity so installation is simple. They offer a full ported ball valve which eliminates clogging and offers rapid discharge of the collected condensate. With this type of unit, the condensed water is gravity fed to the large collection chamber built into the drain rather than sitting unseen somewhere in a separator, cooler or filter within the system. The translucent collection chamber offers a visual indicator of the collected water making it simple to verify the unit is working and most units also incorporate a test button to easily check the unit operation. The key feature for this type of drain is that NO compressed air is lost during the purge cycle!

Unit Operation

Condensate enters the drain through one of two inlet connections. A non-metallic float is tethered to a float arm. As condensate is collected and the translucent reservoir fills, the float rises. When the condensate reaches a design level, the float lifts the trigger assembly and a drain cycle is initiated. The trigger assembly opens and directs control air to the valve actuator, which in turn opens the full-port drain valve. While the drain is open the inlet is blocked to keep all of the compressed air contained for use within the system.

Condensate will then exit the unit. As the condensate level drops, the trigger assembly closes and the valve actuator closes the drain valve. The drain is returned to a standby condition.

Obviously the premier product also carries a premier price. The zero air loss drains are substantially more expensive than solenoid or ball valve drains but offer a quick ROI based on zero compressed air loss, no electricity consumption and increased reliability.

A word of caution: The above pictured unit is a Dehydra 52 by Air System Products. Reading the unit operation paragraph above it is important to note the the float is non-metallic. Other manufacturers uses metal floats and a magnet to facilitate the drain cycle. These units have been known to fail when metal particles (pipe scale) enter the system and attach to the magnet thus decreasing the holding capacity of the magnet to hold the float in place during the drain cycle.