We previously discussed how to get the air moving and the role of the impeller in a centrifugal air compressor. Now that we have air moving at a high rate of speed we need to slow it down. Slow it down? Speed up, Slow down – sounds like old people driving on Sunday morning!

I went in search of a great description for today’s topic, the diffuser. Below is an excerpt from Wikipedia:

As the flow continues into and through the centrifugal impeller, the impeller forces the flow to spin faster and faster. According to a form of Euler‘s fluid dynamics equation, known as pump and turbine equation, the energy input to the fluid is proportional to the flow’s local spinning velocity multiplied by the local impeller tangential velocity.

In many cases the flow leaving centrifugal impeller is near the speed of sound (340 metres/second). The flow then typically flows through a stationary compressor causing it to decelerate. These stationary compressors are actually static guide vanes where energy transformation takes place. As described in Bernoulli’s principle, this reduction in velocity causes the pressure to rise leading to a compressed fluid.

What?

I’m glad you’ve made it to this point. I’m sure you’re thinking, “Principles & Equations, I just want to know how a centrifugal compressor works?”

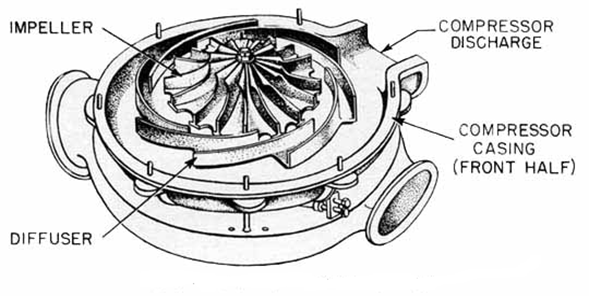

Here goes: The next piece of the centrifugal compressor is the diffuser.

The air leaving the tips of the spinning impeller at high speed now impacts on the stationary diffuser to slow the air down. By slowing the velocity of the air, a rise in pressure is created.

Imagine a car hitting a wall. Until reaching the wall the car moving with only slight resistance from atmospheric air. Note that there is some slight pressure against the car at this point which will be important for later discussion’s. But once it hits the wall the pressure is increased and the increase in pressure collapses the metal of the car.

Same thing when the high speed air hits the diffuser. An increase in pressure, which is what we’re really looking for – compressed air.

Notice the diffuser below is not just a plain wall. It has blades on the surface as well. We don’t really want the air to completely stop (like a car hitting a wall). We just want to slow it down a bit so the pressure will increase.

If you recall discussing the impeller, aerodynamic engineers determine the speed of the impeller along with the length and depth of the impeller blades so the air is moving at the desired velocity. The same is true with the diffuser. The engineer determines the number, length and depth of the blades on the diffuser to slow the high speed air to the pre-determined amount to get just the right amount of pressure rise while maintaining the desired flow of air to the next component of the compressor.