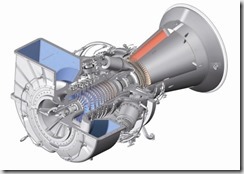

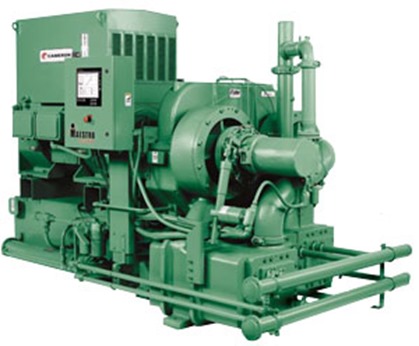

I recently received a phone call from a client asking for some preliminary pricing on a centrifugal compressor that was driven with a natural gas engine. I’ll have to admit, in my years in the compressed air field I had never had this request but I’m always willing to seek out new idea’s.

Contacting my regional engineer for some guidance, I found this is more common than I knew and the factory could accommodate the request for budget pricing.

My clients goal with this project is to meet a corporate mandate that electrical consumption be reduced by 25% over the next several years. His thought was the cost of natural gas could potentially be lower than their cost for electricity or at least near the same. By utilizing natural gas the reduction in electrical consumption could be met. I know over the past few years that many of my power generation clients are moving to mothball coal fired gas plants and they are being replace by natural gas fired plants. Although their direction is being pushed much harder by EPA emission mandates than by fuel cost.

Further researching this type of driver, I found it is much more common in the oil & gas industry than in other area’s of manufacturing. While researching the idea I also found an article written by our friends over at Bechtel Engineering and thought there might be some interest from our readers to look into this further as well.

You can read the overview and download the whitepaper at the following link: http://bit.ly/1RwSjy4

I’ll keep you posted on my clients project and let you know how this progresses and also the determination of how this change would actually pay off in the end from both a reduction of carbon footprint along with overall fuel cost.