Compressed Air Controls

Improving and maintaining compressed air system performance requires not only addressing individual components, but also analyzing both the supply and demand sides of the system and how they interact, especially during periods of peak demand. This practice is often referred to as taking a systems approach because the focus is shifted away from components to total system performance.

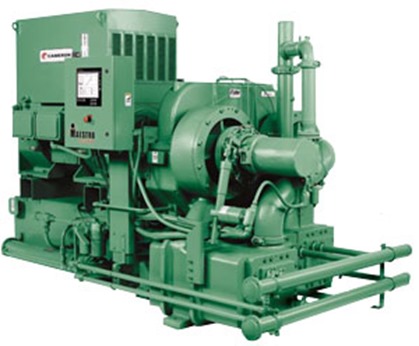

Latest edition controllers from both the OEM and aftermarket suppliers offer the most sophisticated algorithms for unit control and incorporate sensitive digital sensing devices which all combine to give you the most efficient and reliable control. The better control you have of your compressor allows operators to select the lowest possible operating pressure allowing the plant to save significant money on operations and maintenance costs. Almost all of these controllers offer remote monitoring and remote control where operators are not required to be standing by in the compressor area to monitor data points or select update operating methods.

Controls from IZ Systems offer a complete compressor control automation package capable of handling any type of compressor, dryer, cooling tower or chiller system. Thus allowing integrated control of the entire system which further reduces the operations cost and further improves reliability.