Compressed air system’s are complex. Each components carries it’s own difficulties in understanding but once multiples of these components are installed in an industrial plant, a simple area drawing gets complicated really quick.

Before implementing energy reduction strategies, be familiar with all aspects of your compressed air system.

System Supply

Analyze the supply side of your compressed air system for the types of compressors and dryers used, suitability and settings of capacity controls and other operating conditions. Understand the basic capabilities of the system and its various modes of operation. Verify that air compressors are not too big for end uses. For example, an air compressor is oversized if the end use only requires air pressure that is 50 % of the pressure that the compressor is capable of producing. Once the big picture is in view, supply side operating conditions can be modified, within the constraints of the compressed air unit, to better match the demand side uses of compressed air.

System demand

Identify all the uses of compressed air in the plant. Quantify the volume of air used in each application and generate a demand profile, quantity of air used as a function of time, for the compressor. Equipment specifications for operations that use air are good resources for obtaining data on air volume use rates. The profile highlights peak and low demand. A general assessment of compressed air use will help identify inappropriate uses of air.

System diagram

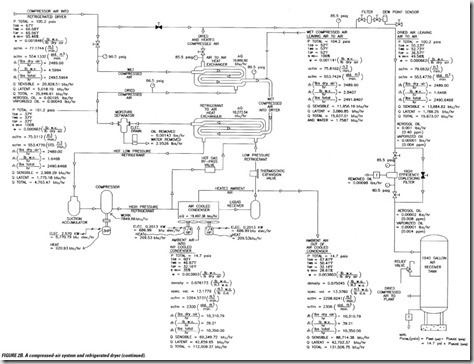

Develop a sketch of your compressed air system including compressors, dryers, receivers, filtration, drain traps, air supply lines with dimensions, and compressed air end uses to provide an overall view of the entire compressed air process.

Distribution system

Investigate the distribution system for any problems related to line size, pressure loss, air storage capacity, air leaks and condensation drains. Verify that all condensation drains are operating properly because inadequate drainage can increase pressure drop across the distribution system.

Maintenance

Evaluate maintenance procedures, records and training. Ensure that procedures are in place for operating and maintaining the compressed air system, and that employees are trained in these procedures.

Qualified audit engineers can give you a complete understanding of your system.