Most all industrial compressed air systems require some type of dryer. The reason is simple, to remove water from the compressed air prior to use downstream.

I saw a recent advertisement with the caption:

I’m not sure how one can determine the “best ways” to dry compressed air without a complete evaluation of the air usage

First things first:

Let’s look at where the water comes from?

Water comes from the atmospheric air that the compressor ingest through the intake. Keep in mind that most plants will look to have compressed air pressure at 100 PSIG. To achieve this pressure the compressor runs a compression ratio of 8 to 1 depending on your physical location. Meaning it must ingest 8 cubic feet of atmospheric air and compress this into 1 cubic foot to achieve the desire pressure.

When you compress 8 cubic feet of air your compressor also compresses all of the contaminants that were in that 8 cubic feet into one cubic foot, including the water that naturally exists in the atmosphere. Its important to know that the air’s ability to hold moisture in a vapor state is directly related to it’s temperature and pressure. In the atmosphere where the pressure is nominally 14.5 PSIA, water will stay in a vapor state until the air reaches it’s saturation point. ie. all the water it can hold at a given temperature (our pressure is already set at 14.5 PSIA). Once this level is exceeded – it rains. Or the water that was previously in a vapor state now converts to liquid form.

The same circumstance is happening inside the pipes of your compressed air system. Once you compress all of the contaminant (in this case water) into a single cubic foot, even with the increase in temperature and pressure, there is still more water than the air can hold in a vapor state so it rain inside your pipes. Additionally as the temperature drops the air’s moisture holding capacity will be lowered and water will continue to condense out as a liquid.

Water is extremely detrimental to compressed air uses downstream. To determine what type of dryer your system will require mandates a look at the possible end uses downstream. For example, if the air use downstream is solely to blow metal chips from a machining operation from a blow gun then chances are the water condensing out will not cause a problem. If however, you happen to have robotic paint spraying systems downstream then any water will be devastating not only to the robotics but will likely also ruin the paint finish when water mixes with the coating during the spraying process.

An additional consideration should also be reviewed, the ambient conditions! In your area are freezing temperatures observed at any time during the year? If the answer is yes then are any compressed air lines exposed to outdoor temperatures. For example, if the above mentioned application of blowing metal chips from a machining operation is the compressed air use (which wouldn’t require a dryer), but the compressors are located in a remote building and the pipe travels outside to the machining building then it would be likely that the air line between buildings could freeze in the winter thus shutting down your machining operation.

Once an assessment has been performed to review the uses of compressed air within the plant along with any ambient temperature issue’s, only then can a determination be made as to the type of dryer required, if any.

Obviously there are thousands of potential uses for compressed air and each one comes with it’s own particular concerns. Great news for end users is where air is being used for equipment, the equipment manufacturer will normally provide direction on the quality of air required for their particular machines.

One other consideration to keep in mind while looking to determine the air dryer requirements is the contaminants in the compressed air stream are not limited to water only. Thinking back to our requirement of 8 cubic feet of atmospheric air being ingested into the compressor is that all contaminants in the atmosphere are magnified 8 times during the compression cycle. This mean any particulate, hydrocarbons or other gas fumes that are in proximity of the compressor intake will also be ingested into the compressor. While our series of posts related to air dryers will not cross over to other contaminants it is worth noting that filtration selection usually goes hand in hand with selecting the air dryer.

In the world of compressed air dryers there are 4 basic classifications of dryers that are normally associated with industrial compressed air systems.

Refrigerated Type Dryers

Refrigerated dryers: The principle of operation is similar to a domestic refrigerator or home air conditioning system. The compressed air is cooled in an air-to-refrigerant heat exchanger to about 35°F, at which point the condensed moisture is separated and drained off.

Regenerative Type Desiccant Dryers (adsorbing)

These dryers use a desiccant, which adsorbs the water vapor in the air stream.

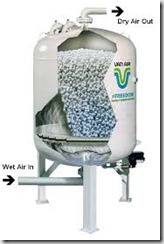

Deliquescent Type Air Dryers (absorbing)

The deliquescent desiccant type dryer uses a hygroscopic desiccant material having a high affinity for water. The desiccant absorbs the water vapor and is dissolved in the liquid formed.

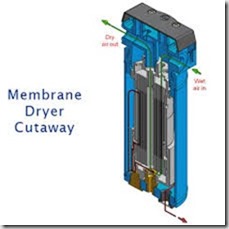

Membrane Type Air Dryers

Specially designed membranes allow water vapor (a gas) to pass through the membrane pores faster than the other gases (air) reducing the amount of water vapor in the air stream at the outlet of the membrane dryer, suppressing the dew point.

Within each classification of air dryer there are different types, each with it’s own operating characteristics. While each type will provide the same end result, their operational modes are different as to be matched to each plants needs and energy requirements as well as initial investment costs.

With the goal of our blog posts to offer small bite size pieces of information that our users can easily digest, we will be writing separate posts for each classification of dryer over the next few weeks. This will allow our readers to learn about each classification and type of dryer as their needs require or the ability to review all of the posts for a comparative overview.

As always, if there are questions, feel free to contact us for additional assistance.