Last week we began our review of regenerative dryers and covered the heatless type. This week we discuss the various types of heated regenerative dryers.

Heated Regenerative Dryer

Heat reactivated regenerative desiccant dryers may have internal or external heat applied by heaters.

There are several different types of heat reactivated regenerative dryers and below we discuss each type along with their advantages and disadvantages. In all heated type regenerative dryers the heat source can be provided by either electric or steam with the most common being electric.

Internally Heated Regenerative Dryer

In the internal type, heaters are embedded in the desiccant bed. This reduces the amount of purge air required for regeneration to less than 10%. The purge air plus radiant heat is used to regenerate the off line desiccant bed. It is also important to consider a cooling cycle to decrease the temperature of the bed prior to bringing it back on line to prevent elevated air temperatures going downstream where the excess heat could damage components. It should be known that in all heater regenerative dryers, when the off line tower is brought back on line there will normally be hotter than average air moving into the process. Even when the air temperature would not cause a problem, the elevated temperatures cause a dew point spike because of the higher temperatures. These can be eliminated with engineering foresight to allow adequate cool down time or by utilizing a period of time that allows dry air to continue to flow through the bed, known as a cooling sweep. Another factor with internal heated regenerative dryers is where earlier stated that activated alumina was typically used in regenerative dryers, this is not the case with an internally heated unit. Due to the heaters being in such close proximity (although normally contained within wells) to the desiccant the temperatures right on the desiccant reaches extremes that do no make activated alumina ideal for this application. Normally a silica gel desiccant is used in these units which can better withstand the increased temperatures. However, silica gel is very sensitive to liquid water and will rupture if subjected to this condition where the pre-filter might not remove all water in a liquid form. To mitigate this potential a layer of activated alumina would be used at the inlet side of the desiccant bed. While performing well, the layered bed arrangement is more difficult when desiccant changes are required and the silica gel desiccant is more expensive than it’s activated alumina counterpart.

Advantages of Internally Heated Regenerative Desiccant Type Dryers include:

- Low dew points can be achieved without potential freeze-up.

- Reduced level of purge air required.

Disadvantages of Internally Heated Regenerative Desiccant Type Dryers include:

- Periodic replacement of the desiccant bed (typically 3-5 years)

- Layered bed is more difficult to change and more expensive

- Oil aerosols can coat the desiccant material, rendering it useless if adequate pre-filtering is not maintained.

- Although reduced, Purge air is required.

Externally Heater Regenerative Dryer

In externally heated regenerative desiccant dryers, the purge air is heated to an elevated temperature with the heater being located outside of the desiccant bed. The heated air then passes through the desiccant bed. to achieve the desired regeneration the amount of purge air is approximately 10% of the dryers rated flow.

Advantages of Externally Heated Regenerative Desiccant Type Dryers include:

- Low dew points can be achieved without potential freeze-up.

- Activated Alumina desiccant

Disadvantages of Externally Heated Regenerative Desiccant Type Dryers include:

- Periodic replacement of the desiccant bed (typically 3-5 years)

- Oil aerosols can coat the desiccant material, rendering it useless if adequate pre-filtering is not maintained.

- Although reduced (less than heatless), Purge air is required.

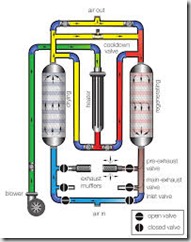

Blower Purge Regenerative Dryer

A heated blower purge type regenerative air dryer incorporates the same (usually larger) external heater as the externally heated type dryer. In this type unit the purge air from the compressed air system can be eliminated by incorporating a blower which uses atmospheric air in place of the compressed air that has been discussed on the previous type of units. The trade off here is the blower consumes additional electricity but is decidedly more efficient than the air compressor itself. This also allows all of the compressed air to be utilized by the plant as none is required for dryer regeneration.

Advantages of Externally Heated Blower Purge Regenerative Desiccant Type Dryers include:

- Low dew points can be achieved without potential freeze-up.

- Activated Alumina desiccant

- No purge air required

- All compressed air is available for plant use

Disadvantages of Externally Heated Blower Purge Regenerative Desiccant Type Dryers include:

- Periodic replacement of the desiccant bed (typically 3-5 years)

- Oil aerosols can coat the desiccant material, rendering it useless if adequate pre-filtering is not maintained.

- Blower consumes additional electric

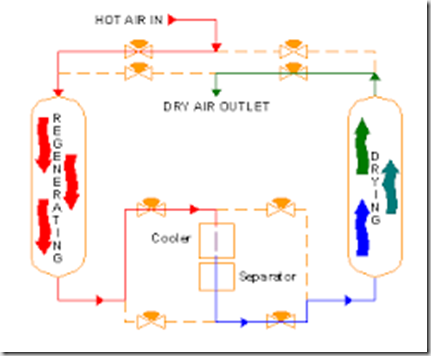

Heat of Compression Type Regenerative Dryers

The heat of compression (HOC) type regenerative dryer is a twin tower type dryer as previously discussed with the primary distinction that the heat required for the regeneration process is taken from the compressor. This process utilizes the heat of compression, thus the naming convention. Some caution must be incorporated into the thought process of utilizing any of these design types. Obviously, the compressor must have the capacity to continuously offer the heat needed for regeneration. In situations where the compressor is running at part load or unloaded, inadequate heat levels could be experienced. If this event occurs there is not enough heat from the compression process to regenerate the offline tower resulting in elevated dew points downstream. While these units can be incorporated into both 2 stage oil free rotary screw compressors as well as centrifugal compressors, the more reliable of these applications are with the 2 stage rotary screw type as the heat levels are typically higher than with a 3 stage centrifugal compressor.

The primary design of the HOC dryer directs all the discharged air from the compressor to the HOC dryer. When using an HOC dryer, the compressor after-cooler is not used. Remember, we need the high temperature air for regeneration. This hot air is first directed to the offline tower or tower that needs regeneration. The hot air at this point is not saturated with water because of the elevated temperature (350 degree F). The air migrates through the offline tower picking up the moisture that is in the desiccant bed from it’s previous work cycle. The air is then directed to an after-cooler where the air is cooled to 100 degrees F and then to a separator to remove the condensed moisture. All of the air is then directed to the online or working bed where it is dried and then exits the dryer to the plant for use.

A second type of design termed “Inter-stage Heat of Compression Dryer” is used on centrifugal compressors by some manufacturers, continues to utilize the compressor after-cooler, cooling the air to 100 degrees F and directing this air to the online or working desiccant bed. A portion of air is taken from the the discharge of the 2nd stage of the compressor where the air is still at elevated temperatures. This air is directed to the offline tower to be used for regeneration where it sweeps the moisture from the bed and the air is then directed to the intercooler downstream of the 2nd stage of compression from where it was taken and prior to the inlet of the 3rd stage. The air passes through the intercooler and into the 3rd stage of compression where it is then compressed to its final pressure and continues the normal flow path through the after-cooler and into the working (online) dryer tower.

Typically 350 degree F air required to regenerate the desiccant bed although 400 degrees F is ideal.

Advantages of Heat of Compression Regenerative Desiccant Type Dryers include:

- Low electrical installation cost

- Low power cost

- No purge air required (Standard Type)

- All compressed air is available for plant use (Standard Type)

Disadvantages of Heat of Compression Regenerative Desiccant Type Dryers include:

- Applicable to only oil free compressors

- One unit required for each compressor (typically)

- Applicable only to compressors having a continuously high discharge temperature

- Inconsistent Dew point

- Susceptible to changing ambient and inlet air temperatures

- Booster heater required for low load conditions

- Slight amount of purge air is required for sweep Cycle (Inter-stage Heat of Compression Dryer)

Filtration

To protect the desiccant bed a coalescing filter is required upstream of the dryer to remove any liquid water and/or vapors that have been ingested by the compressor. To protect downstream equipment from desiccant dust or “fines”, a particulate filter downstream of the dryer also is also recommended.

While on the topic of filtration I would like to interject my personal opinion that a heated type regenerative dryer should NOT be used with lubricated type air compressors. I have witnessed instances where oil contamination from the compressor reached and collected on the desiccant. This not only renders the desiccant useless but is also a fire hazard as bed temperatures can reach over 400 degrees F.