Last week I announced the new best centrifugal compressor available from Fluid Energy. This week I want to bring even more from our product line additions.

Fluid Energy has always been the premier source for centrifugal compressor applications but we want to offer even more. Being the foremost source for centrifugal compressors allows us a position to help a great number of clients. Our only apprehension was there remained a great number of clients with smaller oil free compressed requirements that we simply could not assist. These smaller applications called for a different technology utilizing oil free screw or oil-less scroll compressors. Over the years Fluid Energy has been approached by a number of manufacturers looking for premier representation of their product line. Unfortunately, none of these manufacturers met the exacting standards that the Fluid Energy team requires from the products it represents.

That Changes Now!

Our distribution agreement with Hitachi positions Fluid Energy to cover ALL of your oil-free compressed air requirements. Hitachi, being the world leader in oil-free rotary screw and oil-less scroll compressor technology, lets us assist facilities previously left to less qualified vendors. Now even the smallest facilities (or small applications within large accounts) can receive the Best-In-Class products and service from Fluid Energy!

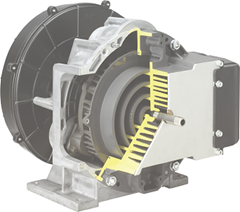

The most concerning aspect of oil free rotary screw compressors is the built in failure point – rotor coatings! With no oil in the compression chamber (air end) to act as a sealing mechanism, the rotors of an oil free rotary screw compressor require a coating to act as a seal thus allowing the intermeshing rotors to compress the air. As the coating degrades, the efficiency of the air end diminishes and ultimately will no longer compress the air to the design point which requires a costly air end replacement. A large competitive supplier of oil free rotary screw compressors even states in their operation manual the life expectancy of the air end at 5 years!

Features & Benefits

- With Hitachi’s patented HX18, Teflon-free coating over their stainless steel rotors our clients can be assured that air end failures from coating degradation are a thing of the past.

- Hitachi’s two stage air cooling system offers a patented stainless steel high pre-cooler which eliminates the opportunity for thermal fatigue of the after cooler thus allowing increase efficiency and reliability.

- The standard equipment “motorized isolation valve” assures moisture causing corrosion is eliminated.

- The included mist eliminator assures no oil deposits are in the ambient air.

- ISO class 0 certification

- With Hitachi US headquarters located in Charlotte, NC along with Fluid Energy’s various Southeast maintenance facilities, replacement parts & service are a quick phone call away.

- CSG: Customer Satisfaction Guarantee offers a 3 year bumper to bumper warranty including parts & labor with an optional extended air end warranty assure end users their plant will be running at peak efficiency for years to come.

- Factory Trained and Certified service technicians.

See Inside The Future

See all the features in the product Video here

Oil-Less Scroll Compressor

For even smaller applications the Hitachi oil-less scroll compressor is the technology to fit your requirements. From 2.5 to 44 horsepower utilizing single & multiple head designs we can fit a compressor to your requirements up to 145 psig. Hitachi actually manufactures the scrolls used on their compressors while the majority of competitors purchase cheaper scroll heads and simply package them on their base. With only two principal manufacturers of scroll type air compressor heads, wouldn’t you feel more secure knowing the manufacturer of your compressor actually understands the primary component?

Learn more about Hitachi’s SRL Scroll series in the product Video

Contact us today to learn more about taking your facility to the “Next” level.