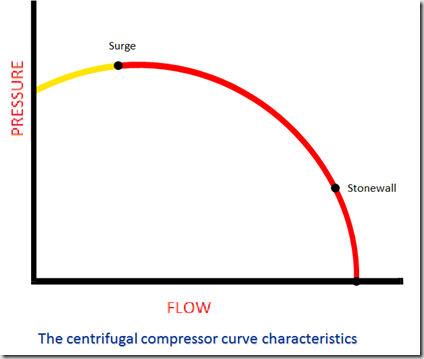

In the segment we’ll discuss two critical characteristics of a centrifugal compressor prior to moving into our discussion of the main controller.

Surge

What is surge?

•Surge is the reversal of flow within a dynamic compression that takes place when the capacity being handled is reduced to a point where insufficient pressure is being generated to maintain flow.

In layman terms, this means that for the flow through the compressor at a given point, the pressure has reached the maximum limit the impeller of the compressor can push against. Therefore, since the compressor cannot overcome the pressure, the air flow slips backwards rather than being pushed into the system.

•This condition can potentially damage the compressor if it is severe and is allowed to remain in that state for a prolonged period; therefore, control and prevention is required.

The resulting problem with a surge condition is twofold:

- The backward flow of air causes severe vibration within the compressor potentially resulting in damage to internal components.

- As air is compressed, heat is generated. When a surge occurs, the air has been compressed (to a certain point) which has heated the air. The air then slips backwards on the impeller and will be grabbed at some point by the impeller to be compressed (moved forward in the compression sequence) at which point it is heated again. As we previously discussed, the temperature of the air moving from stage to stage plays a large part in the design of the entire compressor and at this point we are heating the air above it’s intended design point.

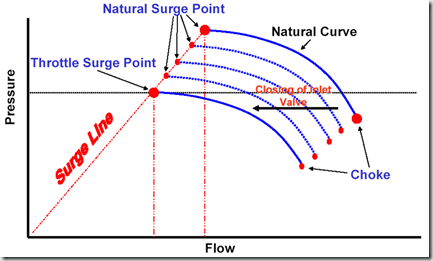

The term surge should also be clarified as the term can have multiple meanings.

Surge Terminology in Centrifugal Compressors:

•Throttle Surge – When flow across the compressor drops till the surge line while maintaining constant pressure.

• To prevent such occurrence, the bypass valve is open before reaching the surge point

• Natural Surge – When pressure reach the maximum the compressor can compress (exceed the physical limitation of the compressor).

•Typically 110% of compressor rated pressure

Stonewall

Stonewall is the effect at the opposite side of the curve from the surge point in the chart above. At some point, as the discharge pressure falls and the airflow through increases at full load, the physical limitations will not allow more air through the stages — this point is known as stonewall. Continued operation at or beyond this point can cause such high flow rates with greater pressure differential that the impellers will not totally fill the vane areas and a cavitation-like action will occur, creating another type of surge with damaging vibrations.