SUMMER! It’s almost here. Can you feel the heat?

You’re not the only thing affected by Hot Weather –

Your Compressed Air System Suffers As Well!

The pain of hot weather on your compressed air system.

Hot weather brings a myriad of problems for your compressed air system. A complete maintenance plan can minimize the impact. Contact us today for a complete system evaluation!

Pain Points

1: Lower Flow Rates

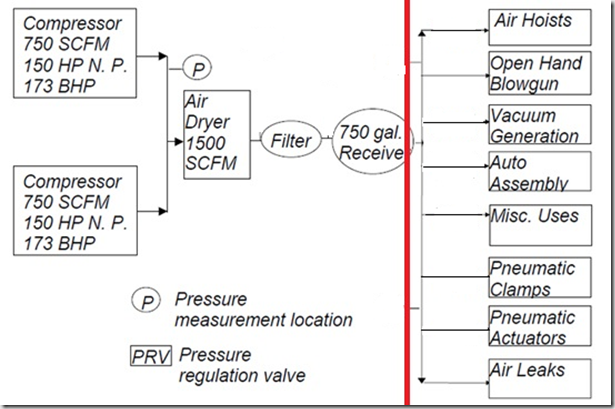

Increased temperatures reduces the density of the ambient air. This means a lower volume of air is being drawn through the intake. While the decreased horsepower requirement might be helpful for the electric bill, the plant is receiving less air. Hopefully when you initially sized your compressor this was taken into account.

2: Reduced Turndown

The effective operating range of the compressor where efficient regulation through the use of a throttle valve or inlet guide vanes is possible is now reduced due to the elevated intake air temperature.

3: All Temperatures go up

The increase in ambient temperatures also effect the temperature of your cooling water (or air for an air cooled compressor). This means the inter-stage temperature increase further reduces your compressor efficiency.

4: More Water

The elevated ambient temperatures means the air can hold more water vapor. Added to the normal increase in humidity during summer months your filtration and drying system now have a much higher work load to provide the clean dry air your plant needs.

5: Automatic Drains

With the increased water loads, your automatic drains have to cycle more frequently to discharge the moisture removed from the system. This can quickly lead to failures.

What to do?

1: Change the oil.

If using petroleum based lubricants, Summer heat and humidity exact a heavy toll on the compressors oil. High heat and humidity can reduce the life of your oil by as much as half in some cases. Give your compressor a fighting chance by changing the oil and filter before the summer bake starts. Changing oil/fluid on schedule maintains proper viscosity for better lubrication and removes moisture, acids, wear metals and other contaminants. If your compressor is using a synthetic based lubricant perform an oil analysis just before the hot weather begins to assure it’s in the best possible condition.

2: Check the fluid system.

To ensure proper cooling and lubrication, and to prevent unscheduled downtime, ensure there are no restrictions in the compressor’s fluid circulation. Regardless of oil type now is a great time to change the oil filter.

3: Change the inlet filter.

Changing the inlet filter on schedule will keep compression efficiency up and maintain proper operating temperature. Remember there is less air drawn through the inlet so keep restrictions as low as possible.

4: Check your drive couplings.

Direct drive couplings are designed for long life but should be checked for signs of wear to avoid unexpected downtime.

5: Ventilate the compressor room.

Poor ventilation can increase operating temperature, reduce oil life and decrease compressor efficiency. Make sure that you are giving your units enough fresh, cool air to the compressor. The compressor room should have slightly positive pressure. Properly sized louvers and fans may do the job. Consider adding duct work to remove exhaust heat from the room. If you have duct-work with thermostatic controls, make sure it is working properly. Also check other equipment in the compressor room to make sure it is not adding excess heat.

6: Clean the coolers.

Keep the fluid and coolers free of dirt/debris to maintain lowest possible operating and compressed air discharge temperatures. This will make dryers more effective and extend fluid life. Change or clean cooler filter mats if you have them. Keeping the coolers clean is one of the most important things that you can do during the summer months.

7: Check your electrical cabinet.

Dirt and dust can form an insulating layer and build up heat on electrical components. Be sure the cabinet fan works and to clean or replace the filters on the electrical cabinet if present. Use appropriate precautions when cleaning the electrical cabinet!

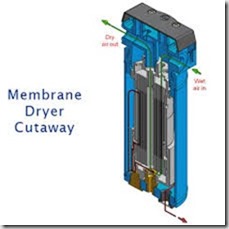

8: Compressed air treatment equipment.

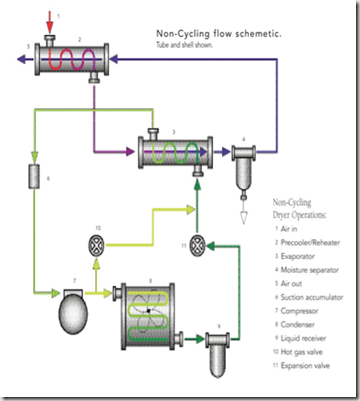

A majority of air treatment equipment is rated at 100 psig inlet, 100 °F inlet temperatures, and 100°F ambient temperatures. During hot summer months, an increase in any of these conditions can often act to decrease the capacity of the equipment. Keeping the aftercooler clean is the first step.

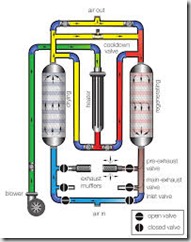

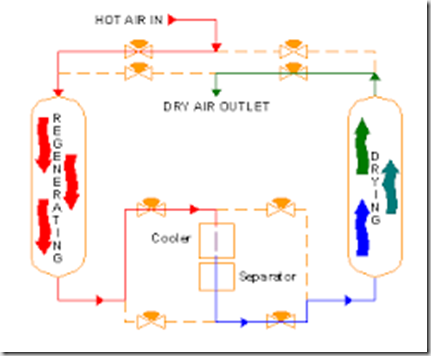

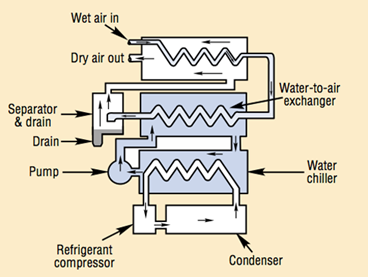

9: Maintain your dryer.

Refrigerated dryers work best when they have a steady supply of clean and cool air or water. Make sure that your dryer is well ventilated and getting the coolest air or water possible. Clean the condenser. If it is stopped up with dirt and debris it can’t do its job and may cause the dryer to overheat. Also check the refrigerant level.

10: Check all drains on tanks, dryer and filters.

Your dryers and filters work hard to remove the extra water that occurs during the hot, humid summer months. Make sure that your drains are functioning properly so that they get that water out of your compressed air. Many drains have test buttons. Adjust timer settings on timed drains if you have them.